The 5W1H analysis is a powerful problem-solving framework that helps individuals and teams systematically explore and address complex issues. This comprehensive approach, derived from the foundational “5W analysis” introduced by Harold Lasswell, has proven invaluable across various domains, from business management to personal development.

Understanding the 5W1H Components

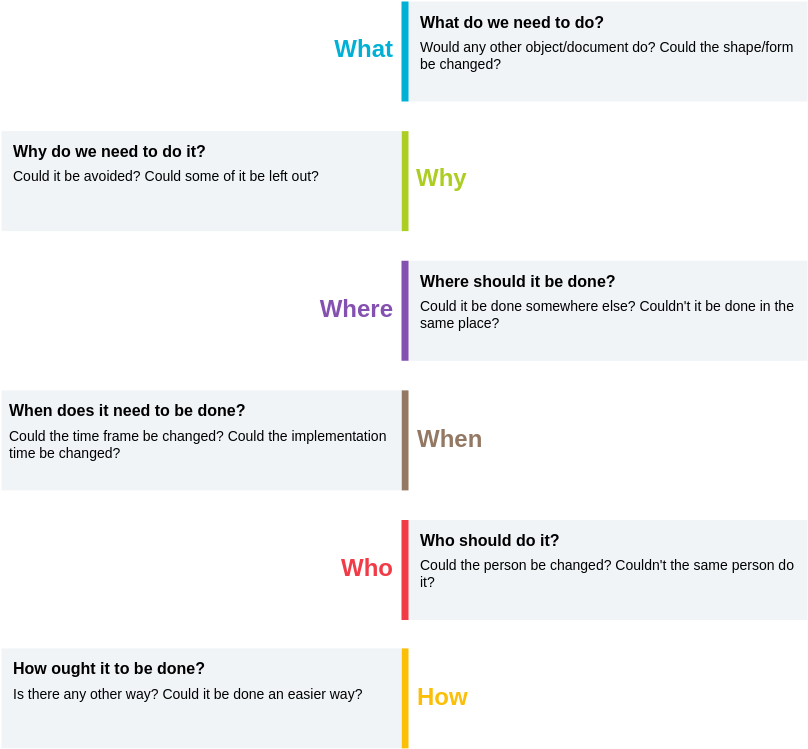

The 5W1H analysis centers around six key questions:

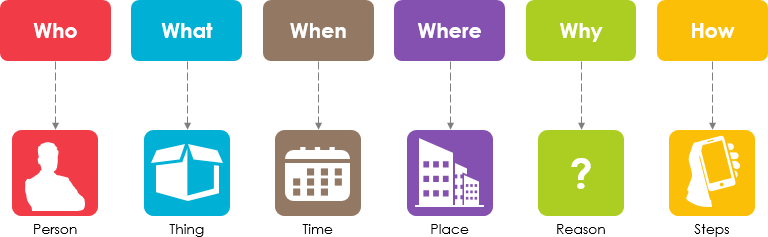

- What: Identifying the core problem or topic at hand.

- Why: Delving into the reasons, causes, and motivations behind the issue.

- When: Establishing the timing, duration, and sequence of events.

- Where: Determining the location, context, and environment.

- Who: Pinpointing the stakeholders, responsible parties, and impacted individuals.

- How: Exploring the methods, processes, and strategies for addressing the problem.

By addressing these interconnected elements, the 5W1H framework provides a structured approach to thoroughly understand and tackle the problem at hand.

Applying 5W1H Analysis

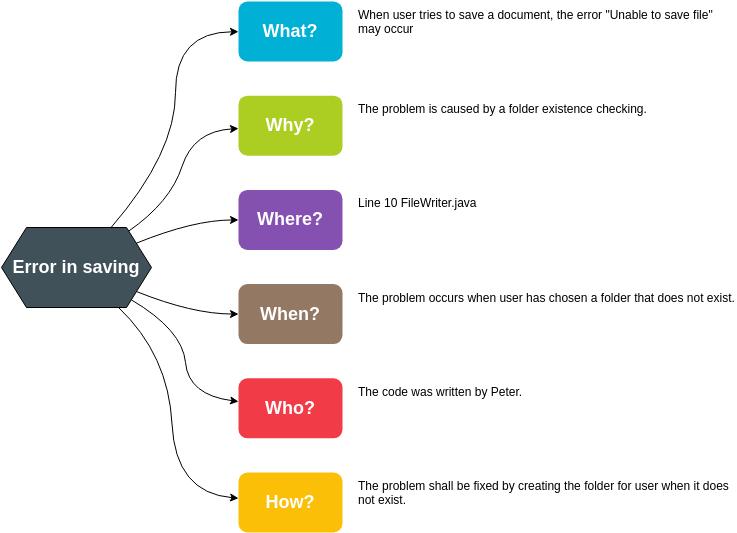

The image provided offers a comprehensive visual representation of the 5W1H analysis applied to a specific topic or problem. Let’s examine how this framework can be used to address the situation:

- What: Clearly defining the problem or topic is the starting point. The image suggests exploring questions such as “What happened?” and “What were the possible causes?”

- Why: Uncovering the underlying reasons, motivations, and assumptions is crucial. The analysis encourages exploring questions like “Why did it happen?” and “Why can’t we do it?”

- When: Establishing the timeline of events, including when the issue first occurred, when it lasted, and when it might be resolved, helps provide crucial context.

- Where: Determining the location, context, and environment where the problem occurred or where the solution needs to be implemented is an essential consideration.

- Who: Identifying the stakeholders, responsible parties, and impacted individuals is vital for understanding the dynamics and mobilizing the right resources.

- How: Exploring the methods, processes, and strategies for addressing the problem is the final step, addressing questions like “How did it happen?” and “How can we do this?”

Applying 5W1H to Problem-Solving

The 5W1H analysis can be effectively utilized in various problem-solving scenarios. Here’s a general action plan:

- Define the Problem: Clearly articulate the issue or topic at hand, using the “What” component of the framework.

- Explore the Causes: Delve into the reasons, motivations, and assumptions behind the problem, addressing the “Why” questions.

- Gather Contextual Information: Establish the timeline, location, and key stakeholders, using the “When,” “Where,” and “Who” components.

- Develop Solutions: Brainstorm and evaluate potential approaches to address the problem, guided by the “How” questions.

- Implement and Monitor: Execute the chosen solution, continuously evaluating its effectiveness and making adjustments as necessary.

By following this structured 5W1H approach, individuals and teams can tackle complex problems more effectively, gain deeper insights, and devise informed and sustainable solutions.

Case Study: Addressing a Critical Equipment Failure Using 5W1H

The Scenario

The organization’s critical production equipment has experienced a sudden and unexpected failure, causing a significant disruption in the manufacturing process. This incident has far-reaching implications, impacting the company’s operations, customer deliveries, and financial performance. Utilizing the 5W1H analysis framework, the management team is determined to thoroughly understand the problem and devise an effective solution to minimize the impact and prevent future occurrences.

Applying the 5W1H Framework

1. What Happened?

The first step is to clearly define the problem. In this case, it is the sudden failure of a critical piece of production equipment. The analysis should explore questions like “What happened?” and “What were the possible causes of the equipment failure?”

2. Why Did It Happen?

Delving into the reasons behind the equipment failure is crucial. The analysis should address questions such as “Why did it happen?” and “Why can’t we restore the equipment to full functionality?” This will help uncover the underlying technical, operational, or maintenance-related factors that contributed to the problem.

3. When Did It Occur?

Establishing the timeline of events is essential for understanding the context. Questions like “When did the equipment first fail?” and “When did it last operate without issues?” will help determine the sequence of events and identify any potential patterns or triggers.

4. Where Did It Take Place?

The location and environment where the equipment failure occurred are also important factors to consider. The analysis should address questions like “Where did the equipment failure happen?” and “Where else in the production process could this issue arise?” to understand the contextual factors that may have influenced the situation.

5. Who Was Involved?

Identifying the key stakeholders, responsible parties, and impacted individuals is vital for addressing the problem effectively. The analysis should explore questions such as “Who was operating the equipment when it failed?”, “Who is responsible for the equipment’s maintenance and repair?”, and “Who could help resolve the issue?” to ensure all relevant perspectives are considered.

6. How Did It Happen?

The final step is to understand the specific methods and processes that led to the equipment failure. The analysis should address questions like “How did the equipment fail?” and “How could we prevent or mitigate similar failures in the future?” to identify the technical, procedural, or operational factors that contributed to the problem.

Here is a summary of the key findings from the case study presented in a table format:

| 5W1H Component | Key Findings |

|---|---|

| What Happened? | – Sudden and unexpected failure of a critical production equipment

– Far-reaching implications on operations, customer deliveries, and financial performance |

| Why Did It Happen? | – Underlying technical, operational, or maintenance-related factors that contributed to the equipment failure

– Inability to restore the equipment to full functionality |

| When Did It Occur? | – Timeline of the equipment failure, including when it first happened and when it last operated without issues

– Identification of any potential patterns or triggers |

| Where Did It Take Place? | – Location and environment where the equipment failure occurred

– Potential for the issue to arise elsewhere in the production process |

| Who Was Involved? | – Individuals operating the equipment when it failed

– Parties responsible for equipment maintenance and repair >- Stakeholders who could help resolve the issue |

| How Did It Happen? | – Technical, procedural, or operational factors that led to the equipment failure

– Potential ways to prevent or mitigate similar failures in the future |

Developing a Comprehensive Action Plan

By thoroughly addressing the 5W1H components, the organization can gain a comprehensive understanding of the equipment failure and develop a well-informed action plan. This may include:

| Action Item | Key Elements |

|---|---|

| Root Cause Analysis | – Conduct a detailed investigation to identify the underlying technical, maintenance, or operational factors that led to the equipment failure |

| Equipment Repair and Maintenance | – Implement a robust plan to restore the equipment to full functionality

– Source necessary parts and engage expert technicians – Enhance the preventive maintenance program |

| Process Improvements | – Evaluate production workflows, quality control measures, and equipment monitoring systems

– Identify opportunities to enhance efficiency and prevent future failures |

| Stakeholder Communication | – Ensure effective communication with affected customers, suppliers, and internal teams

– Coordinate the response and recovery efforts |

| Contingency Planning | – Establish a clear timeline for implementing corrective measures

– Develop contingency plans to minimize the impact on production and customer deliveries |

By executing this action plan, the organization can effectively resolve the current equipment failure, minimize the impact, and lay the foundation for a more resilient and reliable production system.

Conclusion

The 5W1H analysis has proven to be a valuable tool in addressing the critical equipment failure, providing a structured approach to thoroughly understand the problem and develop a comprehensive solution. By systematically addressing the “What,” “Why,” “When,” “Where,” “Who,” and “How” elements, the organization has gained crucial insights, identified the root causes, and formulated an action plan to restore normal operations, prevent future occurrences, and minimize the overall impact on the business. Leveraging the 5W1H framework has enabled the organization to respond effectively to this crisis and emerge stronger, with enhanced resilience and preparedness for potential future challenges.